Braking resistor for rolling stocks to be used on vehicle roof.

Braking resistors for assembly on the roof of the traction unit are most commonly used in: low-floor trams, light trains powered from electric traction, light trains powered by a diesel engine, electric buses, hybrid buses.

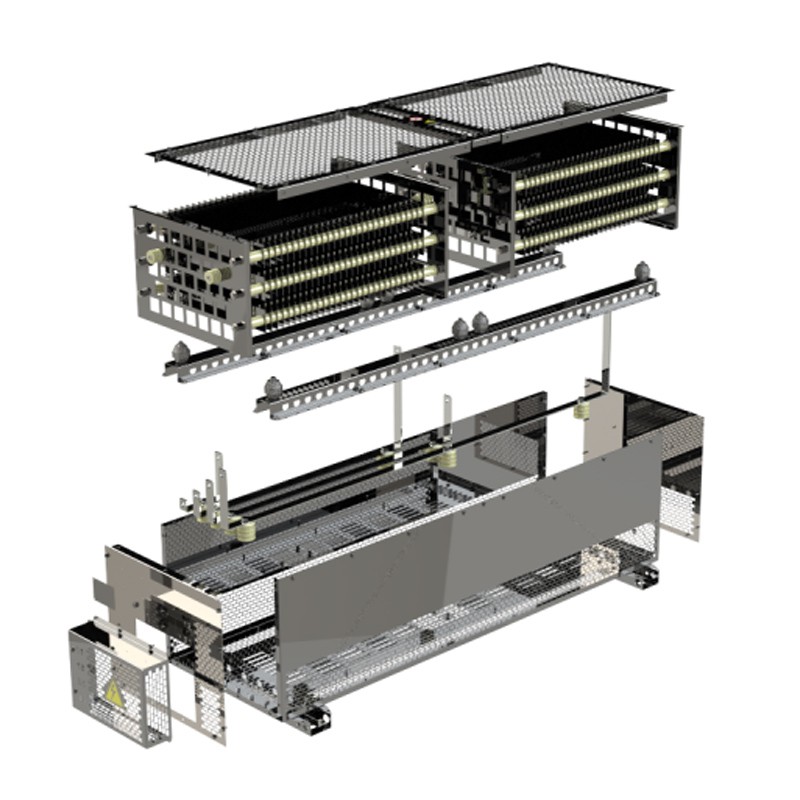

An example of a roof resistor design

Braking resistor of the roof design is made of ribbon or steel grid resistance elements placed in the enclosure made of mesh. It is a so-called open design resistor compliant with EN-60322. Such resistor consists of 2 resistance modules (in some cases one module) that are connected to the braking chopper.

The most important features of the resistor design:

The design is resistant to weather conditions.

The resistor is of so-called open design compliant with the EN-60322 standard with the IP20, where resistor’s active elements (being under voltage) are exposed to atmospheric conditions such as: rain, snow, pollution, etc. It is made entirely of stainless materials, or covered with anti-corrosive layers (copper busbars). It has a rainwater drainage system.

Konstrukcja odporna na wibracje:

Poszczególne połączenia części konstrukcji rezystora są wykonane połączeniami śrubowymi (brak spawania), przez co zwraca się szczególną uwagę na odpowiedni dobór rodzaju połączeń śrubowych oraz momentów ich dokręcania. Rozwiązanie takie gwarantuje, że połączenia nie rozkręcą się podczas pracy na pojeździe. Dodatkowo dla rezystorów prototypowych wykonywane są badania odporności na wibracje zgodnie z normą EN-61373

Vibration resistant design:

The individual connections of the resistor design parts are made with screw connections (no welding), which pays special attention to the appropriate selection of the screw connection type and the tightening torques. This solution guarantees that the connections will not be unscrewed while operating on the vehicle. Additionally, for the prototype resistors, vibration resistance tests are carried out in accordance with the EN-61373 standard

The design is resistant to high temperatures.

The resistance elements of the resistors warm up during operation up to temperatures around 600°C, which causes their elongation and the possibility of contact with each other and, as a consequence, internal short-circuits of a resistor. Therefore, the design of SIMPAX resistors is made in such a way as to compensate for the thermal expansion of the steel. Resistor enclosures are made of stainless steel resistant to high temperatures.

Its design includes the following aspects:

- the most efficient air exchange possible, resulting in better cooling of the resistor

- special construction of the bottom of the enclosure protecting against heating the roof of the vehicle above 80˚C, however, ensuring adequate water drainage

- protection against heating of elements located directly behind the resistor while the vehicle is moving – the heat is discharged only upwards

- special orientation of the upper flaps of the enclosure, thanks to which they deform in a controlled manner during heating, without reducing the air gaps from the resistance elements

- outputting resistor connection terminals to a place where there are no high temperatures.

Place of installations

Braking resistor is mounted on the roof of the traction unit. Due to the fact that the resistor is an open design (IP20), contaminants can settle on its support insulators. To avoid possible damage, it is not recommended to mount them directly behind the pantograph, because the pantograph graphite can get into the resistor enclosure. Its accumulation on insulators can lead to short-circuit, which makes it necessary to clean the resistor more frequently

Technical parameters of the braking resistor mounted on the roof of the traction unit

|

Number of modules: |

Specify Standard 2 |

|

|

Rated resistance: Rn |

Specify |

[Ω] +7%/-5% according to EN-60322 |

|

Permissible minimum resistance at minimum operating temperature: Rmin |

Specify |

[Ω] It cannot fall below the value causing a higher braking current than the max. chopper current |

|

Permissible maximum resistance – hot resistor |

Specify. Standard Rn + 35% – 40% |

[Ω] It cannot rise above the value causing too little braking resistor power |

|

Rated energy released during braking in the worst case scenario |

Specify |

[J] |

|

Rated braking power |

Results from Energy |

[kW] |

|

Rated work cycle |

Please specify Standard Tram: 15s. operation 60s. break Train: 30s. operation, 90s. break |

|

|

Rated operating voltage Un |

Specify |

[V] EN-50163 |

|

Peak voltage |

Specify |

[V] Occurs, for example, during emergency braking |

|

Pollution degree |

PD4 |

In accordance with EN-50124-1 |

|

Overvoltage category |

OV2 |

In accordance with EN-50124-1 |

|

Rated insulation voltage: Unm |

Depends on Un |

In accordance with EN-50124-1 |

|

Impulse voltage: Uni |

Depends on Un, PD, OV |

In accordance with EN-50124-1 |

|

Insulation test voltage |

ZDepends on Un |

In accordance with EN-60322 |

|

IP rating: |

IP20 |

For the enclosure and the junction box |

|

Cooling type |

Natural |

|

|

Maximum resistor temperature |

Standard 600˚C |

|

|

Maximum instantaneous resistor temperature |

Standard 800˚C |

In emergency situations |

|

Permissible resistor dimensions: |

Specify |

|

|

Operating conditions |

||

|

Ambient temperature |

Specify |

Standard: -25˚C; 40˚C |

|

Max operating altitude a.s.l. |

Specify |

Standard < 1000m n.p.m. |

|

Shock and vibration |

Cat. 1 / Class A all directions |

In accordance with EN-61373 |

|

Permissible load of top of the resistor enclosure (the ability to walk on the enclosure) |

Specify Standard 0 kg |

No entry on the resistor enclosure |

|

Environment corrosivity category |

C5-I |

In accordance with ISO12944-2 |

|

Other |

||

|

Maximum temperature under the resistor |

Standard < 80˚C |

|

|

Sound power level |

≤70dB |

In accordance with IEC 60076-10 at 1 m distance |

|

Flammability category |

A1 |

all materials used in the resistor design are non-flammable |

Types of resistor testing

S – standard, O – option, N – not applicable

|

Type of test |

Type test (for the prototype) |

Routine tests (each unit) |

Standard |

|

Visual inspection |

S |

S |

EN61287-1 |

|

Dimensional verification |

S |

S |

EN 61287-1 |

|

Resistor mass verification |

S |

O |

EN 61287-1 |

|

Resistor marking verification |

S |

S |

EN 61287-1 |

|

Resistor resistance measurement |

S |

S |

EN 60322 |

|

Inductance measurement |

S |

O |

EN 60322 |

|

Resistor temperature increase measurement (test under load) |

O / S |

N |

EN 60322 |

|

Shock and vibration test |

O / S |

N |

EN 61373 |

|

Insulation test |

S |

S |

EN 60322 |

|

Rain exposure test |

O |

N |

EN 60322 |

|

Other types of tests on request |

O |

O |

Applied Standards:

- EN-60322:2011 / Railway applications - Electric equipment for rolling stock - Rules for power resistors of open construction

- EN-50124-1:2006 / Railway applications - Insulation coordination - Part 1: Basic requirements - Clearances and creepage distances for all electrical and electronic equipment

- EN-61373:2011 / Railway applications - Rolling Stock Equipment - Shock And Vibration Tests

- EN-60077:2018 / Railway applications - Electric equipment for rolling stock - Part 1: General service conditions and general rules

- EN-60529:2003 / Degrees of protection provided by enclosures (IP code)